Robot and plc programming

Solutions for your plant with our programmers department.

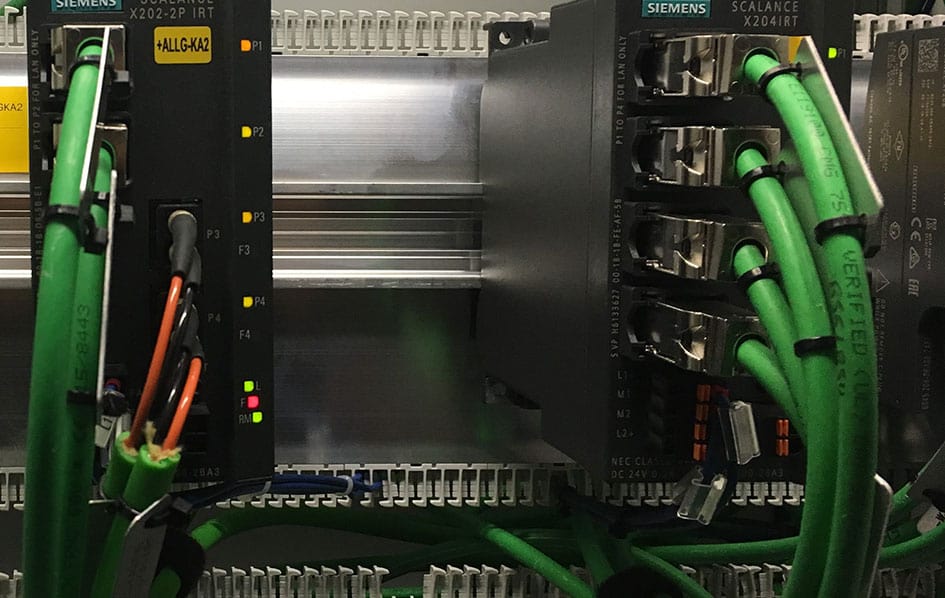

PLC

All installations where a process of maneuvering, control, regulation, signaling, etc. are necessary, incorporate PLCs, as well as a control panel (HMI) used to refer to the interaction between humans and machines.

With innovative design tools we automate routine tasks that require a lot of time, the tasks of control relevant for safety are increasingly present in the field of PLC skills.

For this, we have a PLC and HMI programming department that has a great deal of experience and extensive knowledge of most of the programming languages of the industrial automata on the market such as Siemens, Telemecanique, Omron, Allen-Bradley.

During these last years we have incorporated numerous instrumentation systems aimed at supporting the user in measuring, regulating, observing, transforming and providing security of a given variable in a productive process. We work with multiple brands such as SICK, DANFOSS, IFM, Endress+Hauser, SIEMENS, PHOENIX CONTACT, CIRCUTOR

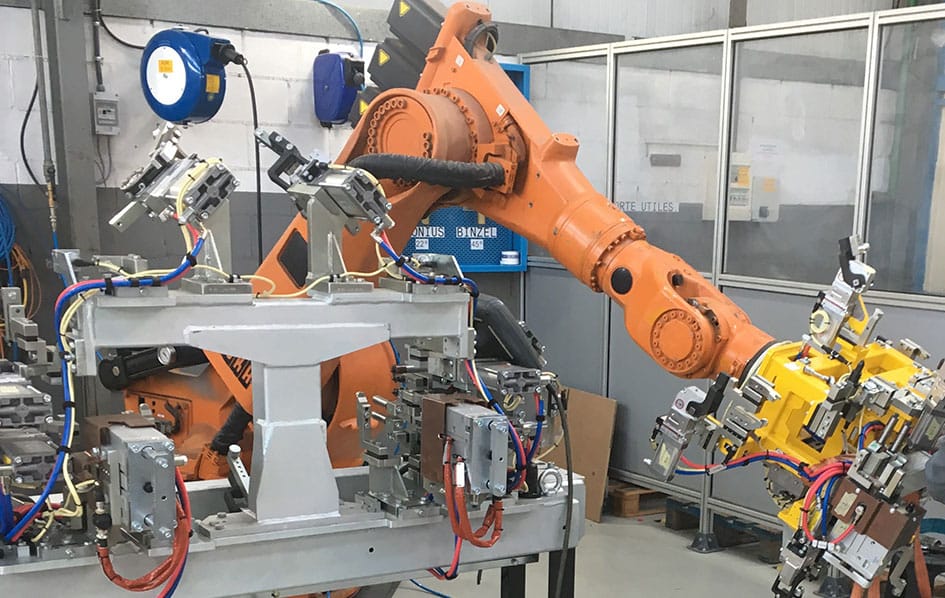

ROBOTS

Robot programming for electric arc welding (MIG / TIG) applications, spot welding (SPOT), materials handling, application of seals and adhesives and painting.

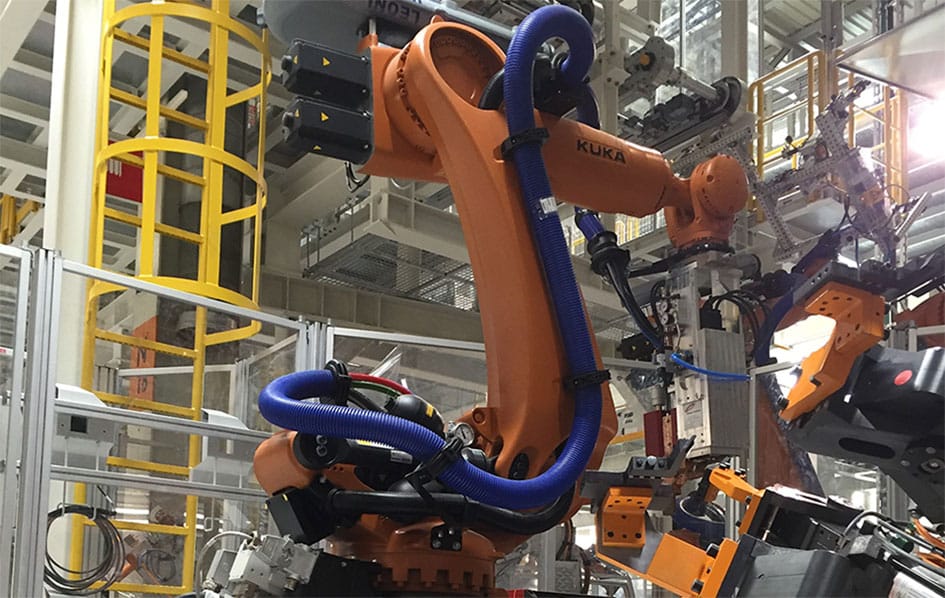

Our team of professionals has extensive experience in the field of robotics in different types and brands of robots designed for jobs of high complexity. (ABB, KUKA, FANUC, YASKAWA). The tasks range from the projection of trajectories to the development of robot-plc logic for the simultaneous interaction of them in the automated islands

- Collaboration of our staff in already formed programming teams

- Development of programming standards according to the client’s needs

- Programming under the most important standards of automobile manufacturers (PSA, Renault, Opel, VW ..)

Given our experience in the world of industrial automation, we also offer services of study and execution of improvements in existing production lines:

- Reduction of cycle times

- Improvement in process quality

- Minimization of energy packet wear

- Analysis of bottlenecks

- Optimization of programs to facilitate their interpretation by the operator

- Design of customized applications for the capture of production data